TEKLEASE®

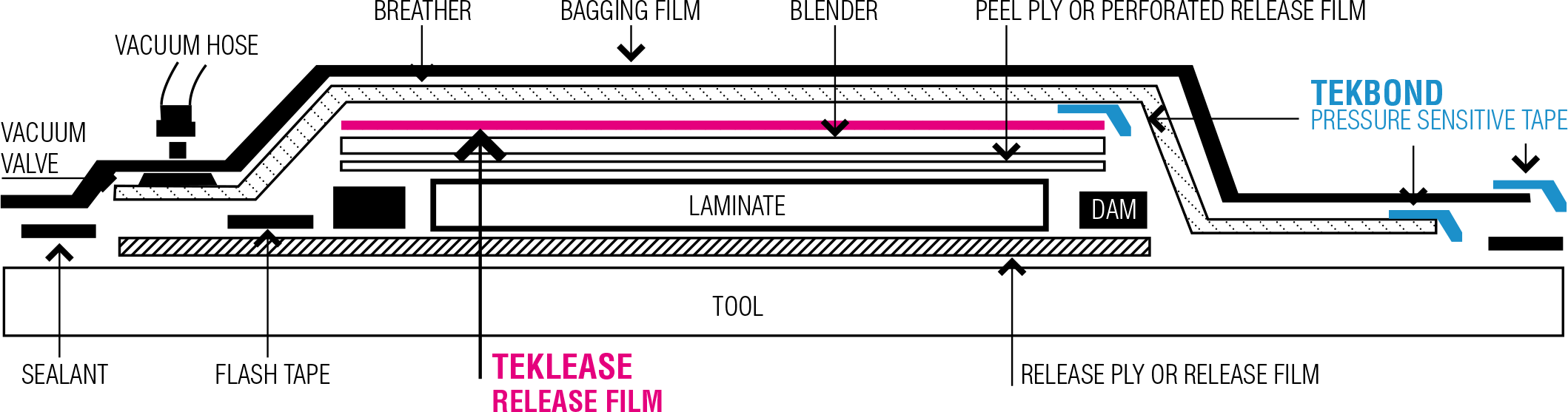

Guarniflon TEKLEASE® release film products have been specially formulated to suit a variety of individual composite process applications. Release films are used to separate and release the laminate from the vacuum stack following the cure of the composite component.

TEKLEASE® films are supplied both as perforated and unperforated to allow resin and volatiles to bleed out of the laminate and coloured for easy identification. The selection of a release film should be based on the resin system being used, the temperature and pressure of the cure cycle, the shape of the component to be cured and the amount of resin bleed that is required.

For example, release films that have higher elongations, will be more suitable for complex curvatures, though tailoring the film is recommended to ensure no bridging of the film occurs. It is important to remember that the mechanical performance of a film is dramatically affected by the presence of the perforations. Rolls of TEKLEASE® should be stored and handled in clean and dry conditions to prevent any contamination onto the final composite component.

TEKLEASE® films are supplied both as perforated and unperforated to allow resin and volatiles to bleed out of the laminate and coloured for easy identification. The selection of a release film should be based on the resin system being used, the temperature and pressure of the cure cycle, the shape of the component to be cured and the amount of resin bleed that is required.

For example, release films that have higher elongations, will be more suitable for complex curvatures, though tailoring the film is recommended to ensure no bridging of the film occurs. It is important to remember that the mechanical performance of a film is dramatically affected by the presence of the perforations. Rolls of TEKLEASE® should be stored and handled in clean and dry conditions to prevent any contamination onto the final composite component.

Material Properties

| CODE | DESCRIPTION | MAX USE TEMP. (°C) | ELONGATION AT BREAK (%) | COLOUR |

|---|---|---|---|---|

| ET6200 | ETFE | 232 | 350 | Blue / Clear |

| FE5000 | FEP | 260 | 280 | Red |

| MRF1 | PTFE | 315 | 250 | Natural |

| MRF2 | Modified PTFE | 315 | 400 | Natural |

Availability

| CODE | THICKNESS (μm) | MAX WIDTH mm. | ROLL LENGTH mm. | OTHER |

|---|---|---|---|---|

| ET6200 | 15, 20, 25, 50 | 1220, 1530, 1780 | 153 | Perforation available |

| FE5000 | 13, 20, 25, 50 | 1220, 1530, 1780 | 153 | Perforation available |

| MRF1 | 25, 50 | 1220 | On request | Perforation available |

| MRF2 | 25, 50 | 1220 | On request | Perforation available |

PROPRIETÀ MATERIALE

| CODE | DESCRIPTION | MAX USE TEMP. (°C) | ELONGATION AT BREAK (%) | COLOUR |

|---|---|---|---|---|

| ET6200 | ETFE | 232 | 350 | Blue / Clear |

| FE5000 | FEP | 260 | 280 | Red |

| MRF1 | PTFE | 315 | 250 | Natural |

| MRF2 | Modified PTFE | 315 | 400 | Natural |

DISPONIBILITÀ

| CODE | THICKNESS (μm) | MAX WIDTH mm. | ROLL LENGTH mm. | OTHER |

|---|---|---|---|---|

| ET6200 | 15, 20, 25, 50 | 1220, 1530, 1780 | 153 | Perforation available |

| FE5000 | 13, 20, 25, 50 | 1220, 1530, 1780 | 153 | Perforation available |

| MRF1 | 25, 50 | 1220 | On request | Perforation available |

| MRF2 | 25, 50 | 1220 | On request | Perforation available |