Teksealing

Special rings for all hydraulic applications where the PTFE compounds are able to grant high wear resistance, low friction even without lubrication, perfect sealing at low, medium and high pressures.

Not only virgin PTFE, but mainly compounds with bronze, carbon and glass fiber.

Not only virgin PTFE, but mainly compounds with bronze, carbon and glass fiber.

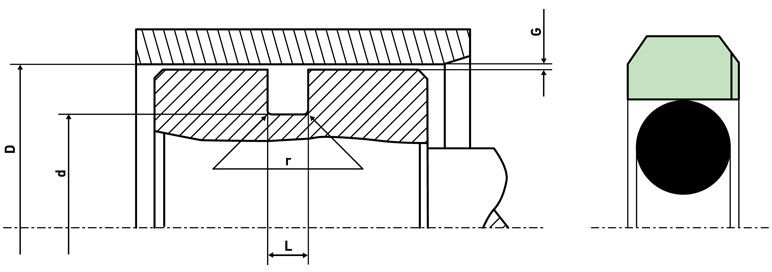

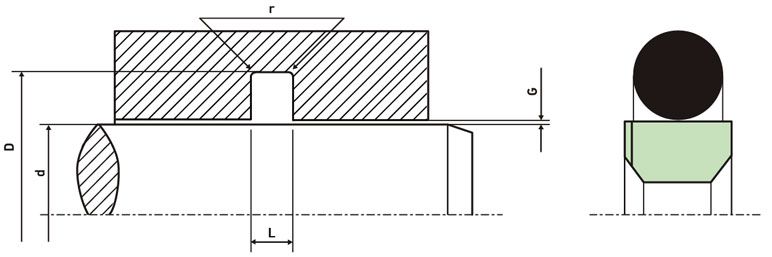

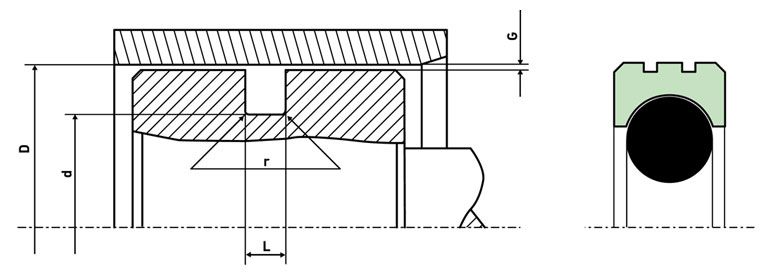

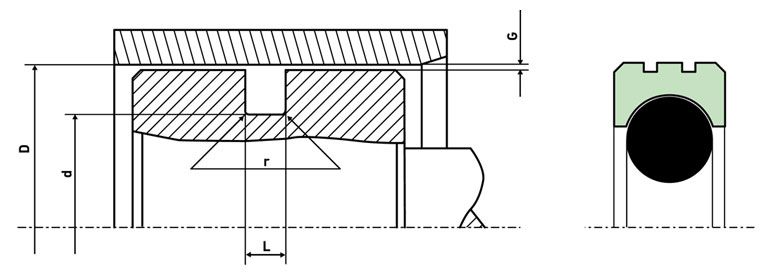

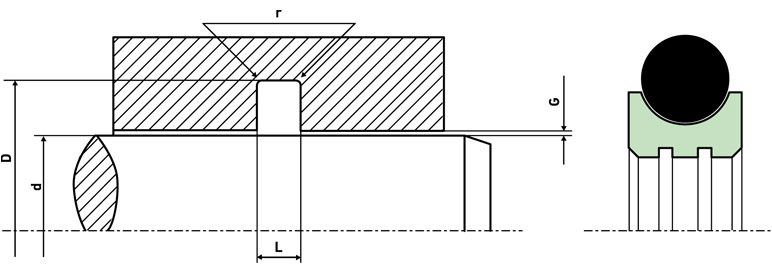

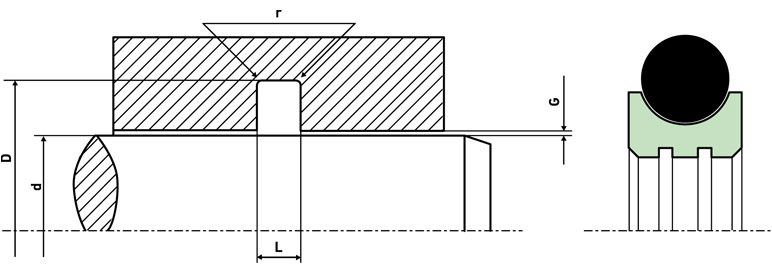

GPS | Double acting seal profile

| DH9 | dh9 | L+0.2 | G | r | O-Ring | |||

|---|---|---|---|---|---|---|---|---|

| GPS-L | GPS | GPS-P | 0÷200 Bar | 0÷400 Bar | ||||

| 15÷39.9 | 8÷14.9 | D-4.9 | 2.2 | 0.6÷0.4 | 0.4÷0.3 | 0.4 | 1.78 | |

| 40÷79.9 | 15÷39.9 | D-7.5 | 3.2 | 0.8÷0.5 | 0.5÷0.3 | 0.6 | 2.62 | |

| 80÷132.9 | 40÷79.9 | 15÷39.9 | D-11.0 | 4.2 | 0.8÷0.5 | 0.5÷0.3 | 1.0 | 3.53 |

| 133÷329.9 | 80÷132.9 | 40÷79.9 | D-15.5 | 6.3 | 1.0÷0.6 | 0.6÷0.4 | 1.2 | 5.34 |

| 330÷669.9 | 133÷329.9 | 80÷132.9 | D-21.0 | 8.1 | 1.0÷0.6 | 0.6÷0.4 | 1.8 | 6.99 |

| 670÷999.9 | 330÷669.9 | 133÷329.9 | D-24.5 | 8.1 | 1.2÷0.8 | 0.8÷0.5 | 1.8 | 6.99 |

| 670÷999.9 | 330÷669.9 | D-28.0 | 9.5 | 1.4÷0.8 | 0.8÷0.6 | 2.0 | 8.40 |

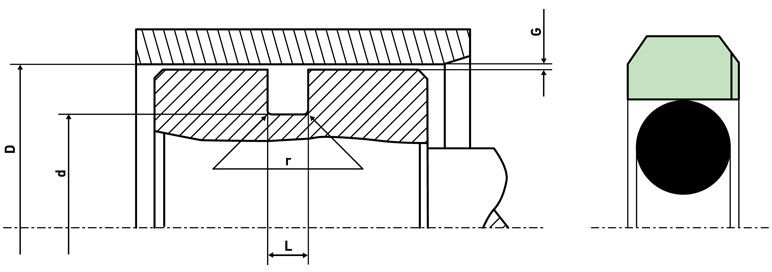

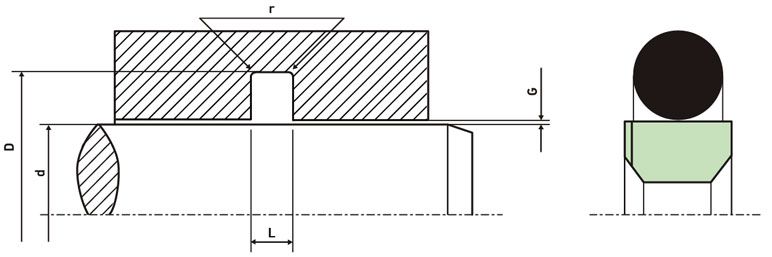

GPR | Essentially one-way seal profile

| DH9 | dh9 | L+0.2 | G | r | O-Ring | |||

|---|---|---|---|---|---|---|---|---|

| GPR-L | GPR | GPR-P | 0÷200Bar | 200÷400 Bar | ||||

| 17÷26.9 | 8÷16.9 | D-4.9 | 2.2 | 0.5÷0.3 | 0.4÷0.2 | 0.4 | 1.78 | |

| 27÷59.9 | 17÷26.9 | D-7.3 | 3.2 | 0.7÷0.3 | 0.5÷0.2 | 0.6 | 2.62 | |

| 60÷199.9 | 27÷59.9 | 17÷26.9 | D-10.7 | 4.2 | 0.8÷0.4 | 0.5÷0.3 | 1.0 | 3.53 |

| 200÷255.9 | 60÷199.9 | 27÷59.9 | D-15.1 | 6.3 | 0,9÷0.6 | 0.6÷0.4 | 1.2 | 5.34 |

| 256÷669.9 | 200÷255.9 | 60÷199.9 | D-20.5 | 8.1 | 1.0÷0.6 | 0.7÷0.4 | 1.8 | 6.99 |

| 670÷999.9 | 256÷669.9 | 200÷255,9 | D-24.0 | 8.1 | 1.1÷0.8 | 0.8÷0.5 | 1.8 | 6.99 |

| 670÷999.9 | 256÷669.9 | D-27.3 | 9.5 | 1.2÷1.0 | 1.0÷0.6 | 2.0 | 8.40 |

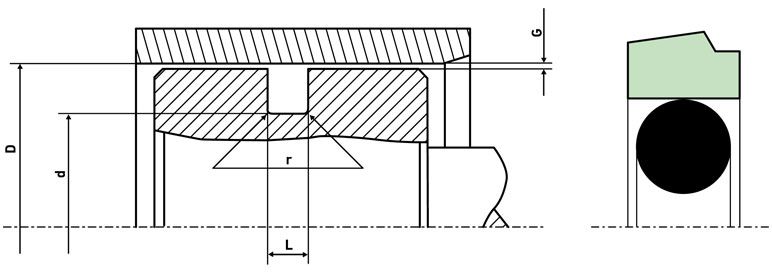

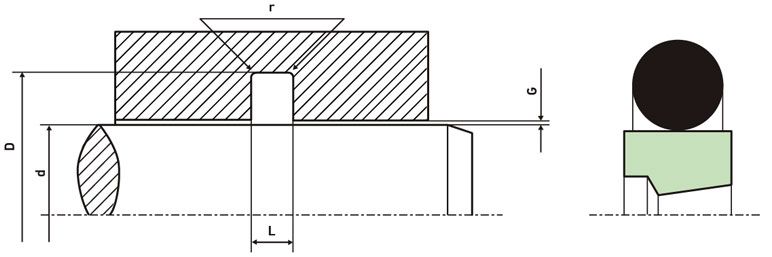

GCS | Double acting seal profile

| d h9 | D H9 | L+0.2 | G | r | 0-Ring | |||

|---|---|---|---|---|---|---|---|---|

| GCS-L | GCS | GCS-P | 0÷200 Bar | 200÷400 Bar | ||||

| 8÷18.9 | 3÷7.9 | d+4.9 | 2.2 | 0.4÷0.3 | 0.3÷0.2 | 0.4 | 1.78 | |

| 19÷37.9 | 8÷18.9 | d+7.3 | 3.2 | 0.5÷0.3 | 0.3÷0.2 | 0.6 | 2.62 | |

| 38÷199.9 | 19÷37.9 | 8÷18.9 | d+10.7 | 4.2 | 0.7÷0.4 | 0.4÷0.2 | 1.0 | 3.53 |

| 200÷255.9 | 38÷199.9 | 19÷37.9 | d+15.1 | 6.3 | 0.8÷0.6 | 0.6÷0.4 | 1.3 | 5.34 |

| 256÷649.9 | 200÷255.9 | 38÷199.9 | d+20.5 | 8.1 | 0.8÷0.6 | 0.6÷0.4 | 1.8 | 6.99 |

| 650÷999.9 | 256÷649.9 | 200÷255.9 | d+24.0 | 8.1 | 0.9÷0.7 | 0.7÷0.4 | 1.8 | 6.99 |

| 650÷999.9 | 256÷649.9 | d+27.3 | 9.5 | 1.0÷0.8 | 0.8÷0.6 | 2.5 | 8.40 |

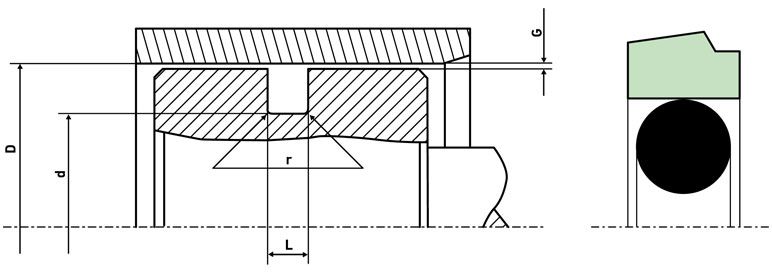

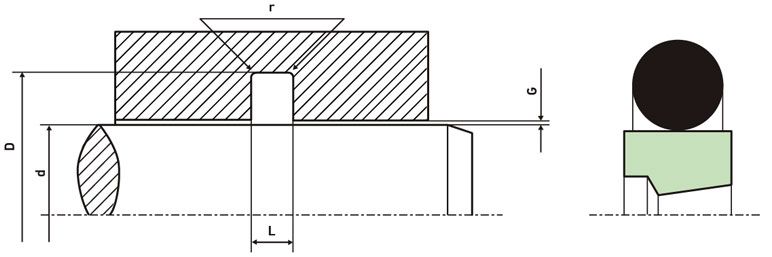

GCR | Essentially one-way seal profile

| d h9 | D H9 | L+0.2 | G | r | 0-Ring | |||

|---|---|---|---|---|---|---|---|---|

| GCR-L | GCR | GCR-P | 0÷200 Bar | 200÷400 Bar | ||||

| 8÷18.9 | 3÷7.9 | d+4.9 | 2.2 | 0.6÷0.4 | 0.4÷0.2 | 0.4 | 1.78 | |

| 19÷37.9 | 8÷18.9 | d+7.3 | 3.2 | 0.8÷0.5 | 0.5÷0.3 | 0.6 | 2.62 | |

| 38÷199.9 | 19÷37.9 | 8÷18.9 | d+10.7 | 4.2 | 0.8÷0.5 | 0.5÷0.3 | 1.0 | 3.53 |

| 200÷255.9 | 38÷199.9 | 19÷37.9 | d+15.1 | 6.3 | 1.0÷0.6 | 0.6÷0.4 | 1.3 | 5.34 |

| 256÷649.9 | 200÷255.9 | 38÷199.9 | d+20.5 | 8.1 | 1.0÷0.6 | 0.6÷0.4 | 1.5 | 6.99 |

| 650÷999.9 | 256÷649.9 | 200÷255.9 | d+24.0 | 8.1 | 1.2÷0.8 | 0.8÷0.6 | 1.5 | 6.99 |

| 650÷999.9 | 256÷649.9 | d+27.3 | 9.5 | 1.4÷1.0 | 1.0÷0.7 | 2.5 | 8.40 |

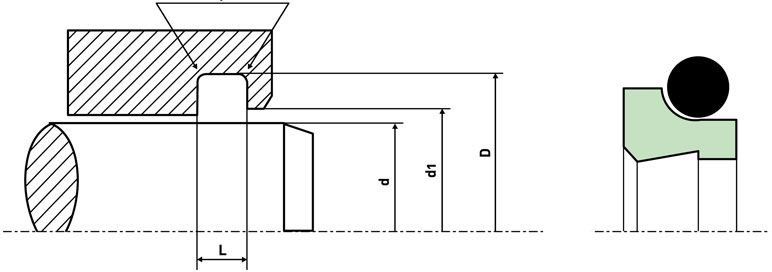

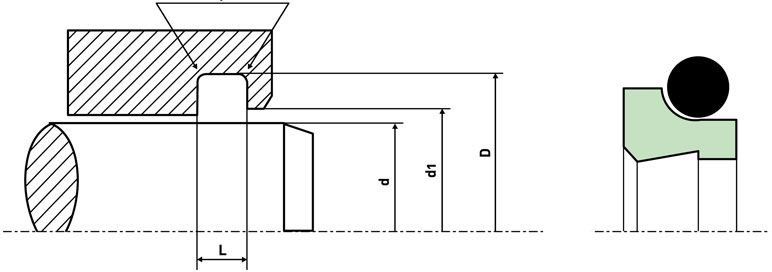

GR/C | Scraper

| d h9 | DH9 | L+0.2 | d1 H1 1 | r | O-Ring |

|---|---|---|---|---|---|

| GR/C | |||||

| 6÷11.9 | d+4.8 | 3.7 | d+1.5 | 0.4 | 1.78 |

| 12÷64.9 | d+6.8 | 5.0 | d+1.5 | 0.7 | 2.62 |

| 65÷250.9 | d+8.8 | 6.0 | d+1.5 | 1.0 | 3.53 |

| 251÷420.9 | d+12.2 | 8.4 | d+2.0 | 1.2 | 5.34 |

| 421÷650.9 | d+16.0 | 11.0 | d+2.0 | 1.5 | 6.99 |

| 651÷999.9 | d+20.0 | 14.0 | d+2.5 | 2.0 | 8.40 |

GPS/R | Rotary seal profile

| D H9 | d h9 | L+0.2 | r | G | 0-Ring | ||

|---|---|---|---|---|---|---|---|

| Serie | 0÷200 Bar | 200÷300 Bar | |||||

| GPS/R-0 | 6÷18.9 | D-4.9 | 2.2 | 0.3 | 0.3÷0.2 | 0.15÷0.1 | 1.78 |

| GPS/R-1 | 19÷37.9 | D-7.5 | 3.2 | 0.5 | 0.6÷0.4 | 0.3÷0.2 | 2.62 |

| GPS/R-2 | 38÷199.9 | D-11.0 | 4.2 | 0.7 | 0.6÷0.4 | 0.3÷0.2 | 3.53 |

| GPS/R-3 | 200÷255.9 | D-15.5 | 6.3 | 1.0 | 0.8÷0.6 | 0.4÷0.3 | 5.34 |

| GPS/R-4 | 256÷649.9 | D-21.0 | 8.1 | 1.2 | 0.8÷0.6 | 0.4÷0.3 | 6.99 |

| GPS/R-5 | 650÷999.9 | D-28.0 | 9.5 | 1.5 | 1.2÷0.9 | 0.6÷0.5 | 8.40 |

GCS/R | Rotary seal profile

| d h9 | D H9 | L+0.2 | r | G | 0-Ring | ||

|---|---|---|---|---|---|---|---|

| Serie | 0÷200 Bar | 200÷300 Bar | |||||

| GCS/R-0 | 6÷18.9 | d-4.9 | 2.2 | 0.3 | 0.3÷0.2 | 0.15÷0.1 | 1.78 |

| GCS/R-1 | 19÷37.9 | d-7.5 | 3.2 | 0.5 | 0.6÷0.4 | 0.3÷0.2 | 2.62 |

| GCS/R-2 | 38÷199.9 | d-11.0 | 4.2 | 0.7 | 0.6÷0.4 | 0.3÷0.2 | 3.53 |

| GCS/R-3 | 200÷255.9 | d-15.5 | 6.3 | 1.0 | 0.8÷0.6 | 0.4÷0.3 | 5.34 |

| GCS/R-4 | 256÷649.9 | d-21.0 | 8.1 | 1.2 | 0.8÷0.6 | 0.4÷0.3 | 6.99 |

| GCS/R-5 | 650÷999.9 | d-28.0 | 9.5 | 1.5 | 1.2÷0.9 | 0.6÷0.5 | 8.40 |

GPS | DOUBLE ACTIN SEAL PROFILE

| DH9 | dh9 | L+0.2 | G | r | O-Ring | |||

|---|---|---|---|---|---|---|---|---|

| GPS-L | GPS | GPS-P | 0÷200 Bar | 0÷400 Bar | ||||

| 15÷39.9 | 8÷14.9 | D-4.9 | 2.2 | 0.6÷0.4 | 0.4÷0.3 | 0.4 | 1.78 | |

| 40÷79.9 | 15÷39.9 | D-7.5 | 3.2 | 0.8÷0.5 | 0.5÷0.3 | 0.6 | 2.62 | |

| 80÷132.9 | 40÷79.9 | 15÷39.9 | D-11.0 | 4.2 | 0.8÷0.5 | 0.5÷0.3 | 1.0 | 3.53 |

| 133÷329.9 | 80÷132.9 | 40÷79.9 | D-15.5 | 6.3 | 1.0÷0.6 | 0.6÷0.4 | 1.2 | 5.34 |

| 330÷669.9 | 133÷329.9 | 80÷132.9 | D-21.0 | 8.1 | 1.0÷0.6 | 0.6÷0.4 | 1.8 | 6.99 |

| 670÷999.9 | 330÷669.9 | 133÷329.9 | D-24.5 | 8.1 | 1.2÷0.8 | 0.8÷0.5 | 1.8 | 6.99 |

| 670÷999.9 | 330÷669.9 | D-28.0 | 9.5 | 1.4÷0.8 | 0.8÷0.6 | 2.0 | 8.40 |

GPR | ESSENTIALLY ONE-WAY SEAL PROFILE

| DH9 | dh9 | L+0.2 | G | r | O-Ring | |||

|---|---|---|---|---|---|---|---|---|

| GPR-L | GPR | GPR-P | 0÷200Bar | 200÷400 Bar | ||||

| 17÷26.9 | 8÷16.9 | D-4.9 | 2.2 | 0.5÷0.3 | 0.4÷0.2 | 0.4 | 1.78 | |

| 27÷59.9 | 17÷26.9 | D-7.3 | 3.2 | 0.7÷0.3 | 0.5÷0.2 | 0.6 | 2.62 | |

| 60÷199.9 | 27÷59.9 | 17÷26.9 | D-10.7 | 4.2 | 0.8÷0.4 | 0.5÷0.3 | 1.0 | 3.53 |

| 200÷255.9 | 60÷199.9 | 27÷59.9 | D-15.1 | 6.3 | 0,9÷0.6 | 0.6÷0.4 | 1.2 | 5.34 |

| 256÷669.9 | 200÷255.9 | 60÷199.9 | D-20.5 | 8.1 | 1.0÷0.6 | 0.7÷0.4 | 1.8 | 6.99 |

| 670÷999.9 | 256÷669.9 | 200÷255,9 | D-24.0 | 8.1 | 1.1÷0.8 | 0.8÷0.5 | 1.8 | 6.99 |

| 670÷999.9 | 256÷669.9 | D-27.3 | 9.5 | 1.2÷1.0 | 1.0÷0.6 | 2.0 | 8.40 |

GCS | DOUBLE ACTING SEAL PROFILE

| d h9 | D H9 | L+0.2 | G | r | 0-Ring | |||

|---|---|---|---|---|---|---|---|---|

| GCS-L | GCS | GCS-P | 0÷200 Bar | 200÷400 Bar | ||||

| 8÷18.9 | 3÷7.9 | d+4.9 | 2.2 | 0.4÷0.3 | 0.3÷0.2 | 0.4 | 1.78 | |

| 19÷37.9 | 8÷18.9 | d+7.3 | 3.2 | 0.5÷0.3 | 0.3÷0.2 | 0.6 | 2.62 | |

| 38÷199.9 | 19÷37.9 | 8÷18.9 | d+10.7 | 4.2 | 0.7÷0.4 | 0.4÷0.2 | 1.0 | 3.53 |

| 200÷255.9 | 38÷199.9 | 19÷37.9 | d+15.1 | 6.3 | 0.8÷0.6 | 0.6÷0.4 | 1.3 | 5.34 |

| 256÷649.9 | 200÷255.9 | 38÷199.9 | d+20.5 | 8.1 | 0.8÷0.6 | 0.6÷0.4 | 1.8 | 6.99 |

| 650÷999.9 | 256÷649.9 | 200÷255.9 | d+24.0 | 8.1 | 0.9÷0.7 | 0.7÷0.4 | 1.8 | 6.99 |

| 650÷999.9 | 256÷649.9 | d+27.3 | 9.5 | 1.0÷0.8 | 0.8÷0.6 | 2.5 | 8.40 |

GCR | ESSENTIALLY ONE-WAY SEAL PROFILE

| d h9 | D H9 | L+0.2 | G | r | 0-Ring | |||

|---|---|---|---|---|---|---|---|---|

| GCR-L | GCR | GCR-P | 0÷200 Bar | 200÷400 Bar | ||||

| 8÷18.9 | 3÷7.9 | d+4.9 | 2.2 | 0.6÷0.4 | 0.4÷0.2 | 0.4 | 1.78 | |

| 19÷37.9 | 8÷18.9 | d+7.3 | 3.2 | 0.8÷0.5 | 0.5÷0.3 | 0.6 | 2.62 | |

| 38÷199.9 | 19÷37.9 | 8÷18.9 | d+10.7 | 4.2 | 0.8÷0.5 | 0.5÷0.3 | 1.0 | 3.53 |

| 200÷255.9 | 38÷199.9 | 19÷37.9 | d+15.1 | 6.3 | 1.0÷0.6 | 0.6÷0.4 | 1.3 | 5.34 |

| 256÷649.9 | 200÷255.9 | 38÷199.9 | d+20.5 | 8.1 | 1.0÷0.6 | 0.6÷0.4 | 1.5 | 6.99 |

| 650÷999.9 | 256÷649.9 | 200÷255.9 | d+24.0 | 8.1 | 1.2÷0.8 | 0.8÷0.6 | 1.5 | 6.99 |

| 650÷999.9 | 256÷649.9 | d+27.3 | 9.5 | 1.4÷1.0 | 1.0÷0.7 | 2.5 | 8.40 |

GR/C | SCRAPER

| d h9 | DH9 | L+0.2 | d1 H1 1 | r | O-Ring |

|---|---|---|---|---|---|

| GR/C | |||||

| 6÷11.9 | d+4.8 | 3.7 | d+1.5 | 0.4 | 1.78 |

| 12÷64.9 | d+6.8 | 5.0 | d+1.5 | 0.7 | 2.62 |

| 65÷250.9 | d+8.8 | 6.0 | d+1.5 | 1.0 | 3.53 |

| 251÷420.9 | d+12.2 | 8.4 | d+2.0 | 1.2 | 5.34 |

| 421÷650.9 | d+16.0 | 11.0 | d+2.0 | 1.5 | 6.99 |

| 651÷999.9 | d+20.0 | 14.0 | d+2.5 | 2.0 | 8.40 |

GPS/R | ROTARY SEAL PROFILE

| D H9 | d h9 | L+0.2 | r | G | 0-Ring | ||

|---|---|---|---|---|---|---|---|

| Serie | 0÷200 Bar | 200÷300 Bar | |||||

| GPS/R-0 | 6÷18.9 | D-4.9 | 2.2 | 0.3 | 0.3÷0.2 | 0.15÷0.1 | 1.78 |

| GPS/R-1 | 19÷37.9 | D-7.5 | 3.2 | 0.5 | 0.6÷0.4 | 0.3÷0.2 | 2.62 |

| GPS/R-2 | 38÷199.9 | D-11.0 | 4.2 | 0.7 | 0.6÷0.4 | 0.3÷0.2 | 3.53 |

| GPS/R-3 | 200÷255.9 | D-15.5 | 6.3 | 1.0 | 0.8÷0.6 | 0.4÷0.3 | 5.34 |

| GPS/R-4 | 256÷649.9 | D-21.0 | 8.1 | 1.2 | 0.8÷0.6 | 0.4÷0.3 | 6.99 |

| GPS/R-5 | 650÷999.9 | D-28.0 | 9.5 | 1.5 | 1.2÷0.9 | 0.6÷0.5 | 8.40 |

GCS/R | ROTARY SEAL PROFILE

| d h9 | D H9 | L+0.2 | r | G | 0-Ring | ||

|---|---|---|---|---|---|---|---|

| Serie | 0÷200 Bar | 200÷300 Bar | |||||

| GCS/R-0 | 6÷18.9 | d-4.9 | 2.2 | 0.3 | 0.3÷0.2 | 0.15÷0.1 | 1.78 |

| GCS/R-1 | 19÷37.9 | d-7.5 | 3.2 | 0.5 | 0.6÷0.4 | 0.3÷0.2 | 2.62 |

| GCS/R-2 | 38÷199.9 | d-11.0 | 4.2 | 0.7 | 0.6÷0.4 | 0.3÷0.2 | 3.53 |

| GCS/R-3 | 200÷255.9 | d-15.5 | 6.3 | 1.0 | 0.8÷0.6 | 0.4÷0.3 | 5.34 |

| GCS/R-4 | 256÷649.9 | d-21.0 | 8.1 | 1.2 | 0.8÷0.6 | 0.4÷0.3 | 6.99 |

| GCS/R-5 | 650÷999.9 | d-28.0 | 9.5 | 1.5 | 1.2÷0.9 | 0.6÷0.5 | 8.40 |

BEARING TAPES

For the heaviest applications in the hydraulic field. motion control and mechanical field. Guarniflon® developed a new family of products. made by special PTFE compounds and devoted technologies. in order to fulfil Guarniflon® customers’ requirements.

Compounded PTFE materials with bronze. carbon. graphite or other fillers are designed to enhance properties such as:

- wear resistance

- coefficient of friction

- compression strength

Thickness from 1.5 mm. up to 5 mm. Width from 4 mm. up to 300 mm.

Available:

Available:

- with sharp edges

- with chamfers on 2 or 4 angles

- knurled on 1 or 2 sides

- etched on 1 or 2 sides

| Rolls Length | |

|---|---|

| Tickness mm. | Length mt. |

| 1.5 | 35 |

| 2 | 25 |

| 2.5 | 20 |

| 3 | 16 |

| 4 | 24 |

MATERIALS

VIRGIN PTFE

Good chemical resistance. Fair wear resistance.

Excellent coefficient of friction.

PTFE + GLASS FIBER

Enhanced wear resistance. Enhanced chemical resistance. Good compression resistance.

PTFE + CARBON

Good thermal and electrical conductivity. Good resistance to deformation. Excellent resistance to load with low coefficient of friction and high wear resistance.

Enhanced chemical resistance.

PTFE + BRONZE

Enhanced compressive strength. Good wear resistance and high thermal conductivity. Guarniflon® has available more than 80 different compounds providing solutions to the most tribological applications. Available on request.

Good chemical resistance. Fair wear resistance.

Excellent coefficient of friction.

PTFE + GLASS FIBER

Enhanced wear resistance. Enhanced chemical resistance. Good compression resistance.

PTFE + CARBON

Good thermal and electrical conductivity. Good resistance to deformation. Excellent resistance to load with low coefficient of friction and high wear resistance.

Enhanced chemical resistance.

PTFE + BRONZE

Enhanced compressive strength. Good wear resistance and high thermal conductivity. Guarniflon® has available more than 80 different compounds providing solutions to the most tribological applications. Available on request.