Etching Technology

The etching process consists in a chemical surface treatment on virgin or filled PTFE. It allows PTFE to be glued on to surfaces of various materials, such as rubber, metal, plastics, etc.

Some of the most common applications are for the tank lining where chemical agents must be stored, machine tool sliding surfaces, coupling with other materials for finished parts, etc. Guarniflon® owns the most updated technologies devoted to the etching process on semifinished (sheets, tapes, tubes, bars) and finished PTFE products, virgin or compounded. The etching process of Guarniflon® is capable of providing uniformly reactive surfaces.

Sheets and skived tapes, etched on one or two sides, are available in the following standard sizes:

Some of the most common applications are for the tank lining where chemical agents must be stored, machine tool sliding surfaces, coupling with other materials for finished parts, etc. Guarniflon® owns the most updated technologies devoted to the etching process on semifinished (sheets, tapes, tubes, bars) and finished PTFE products, virgin or compounded. The etching process of Guarniflon® is capable of providing uniformly reactive surfaces.

Sheets and skived tapes, etched on one or two sides, are available in the following standard sizes:

SHEETS

| Thickness mm. | Sizes mm. |

|---|---|

| min. 1,5 - max. 100 | 600 x 600 |

| min. 1,5 - max. 100 | 1000 x 1000 |

| min. 1,5 - max. 100 | 1200 x 1200 |

| min. 1,5 - max. 100 | 1500 x 1500 |

SKIVED TAPES

| Thickness mm. | Sizes mm. |

|---|---|

| min. 0,020 - max. 4 | min 300 - max 1500 |

QUALITY OF ETCHING

GUARNIFLON® can guarantee the quality of etching by the control of process parameters and by evaluating the extent of etching itself through a wettability test (Contact Angle Method), and an adhesion test (ref. ASTM D903).

MACHINED PRODUCTS

Rings, bushes, parts and other designed products can be etched according to the end use partially or on the total surface.

CONTACT ANGLE METHOD

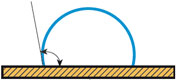

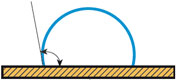

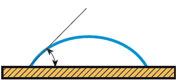

It is based on the measure of the angle between the tangent to a distilled water drop and the PTFE surface (ie, the contact angle).

In Figure 1 two examples of contact angle are illustrated - on unetched surface (poor wetting) and on etched surface (good wetting), respectively.

The relationship in terms of performance between contact angle and etching is shown in Figure 2.

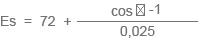

Contact angle and surface energy of etched PTFE are related by the following formula:

In Figure 1 two examples of contact angle are illustrated - on unetched surface (poor wetting) and on etched surface (good wetting), respectively.

The relationship in terms of performance between contact angle and etching is shown in Figure 2.

Contact angle and surface energy of etched PTFE are related by the following formula:

where:

Es = surface energy (dynes/cm)

= contact angle (degrees)

= contact angle (degrees)

Es = surface energy (dynes/cm)

= contact angle (degrees)

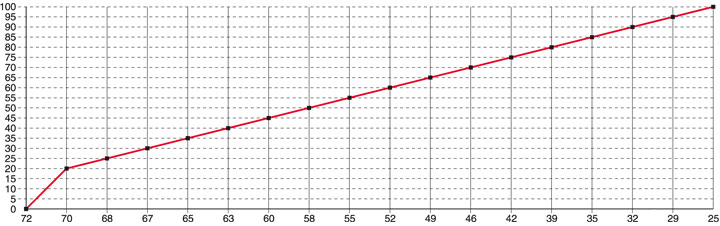

= contact angle (degrees)The graph in Figure 3 shows contact angle vs. surface energy.

Fig.1

Fig.2

| Contact Angle | Degree of Etching |

|---|---|

| 20° - 45° | excellent |

| 46° - 60° | fair |

| > 60° | poor |

Fig. 3

CONTACT ANGLE vs. SURFACE ENERGY SURFACE

ENERGY IN DYNES/CM

CONTACT ANGLE vs. SURFACE ENERGY SURFACE

ENERGY IN DYNES/CM