Teksealing

Anelli di tenuta speciali per tutte le applicazioni idrauliche dove le mescole in PTFE sono in grado di garantire elevata resistenza all'usura, basso attrito anche in assenza di lubrificazione, perfetta tenuta a basse, medie e alte pressioni.

Non solo PTFE vergine, ma soprattutto gradi caricati con bronzo, fibra di vetro e carbone.

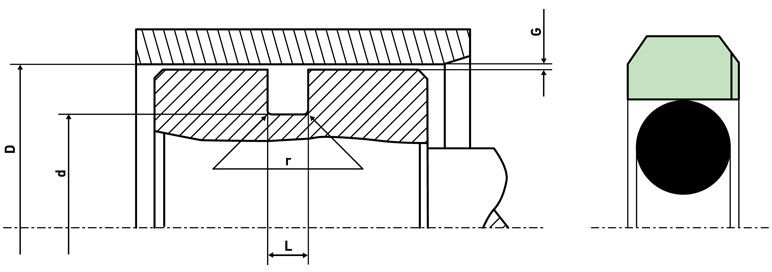

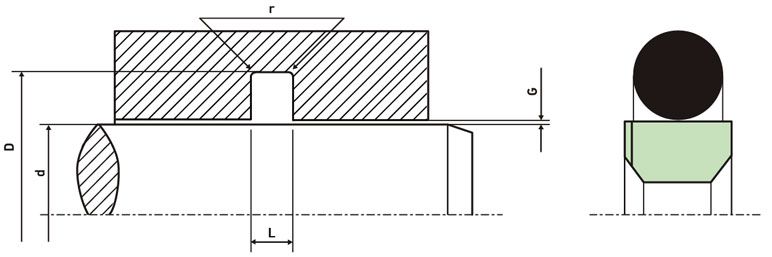

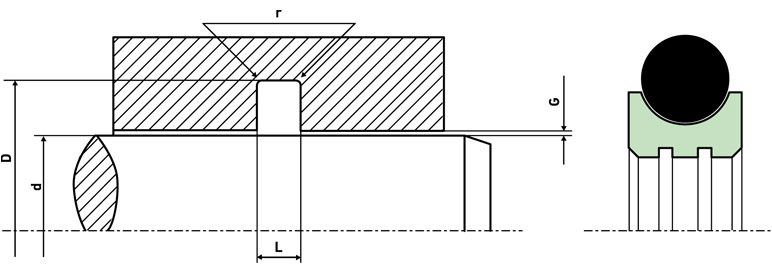

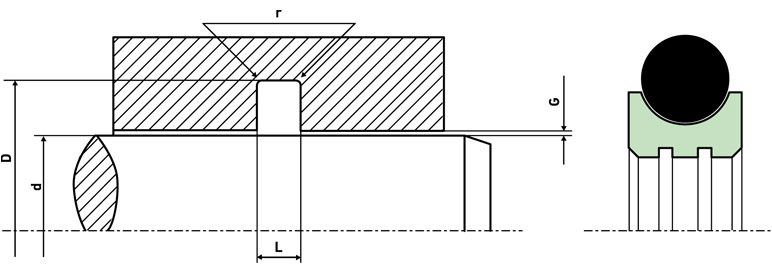

GPS | Double acting seal profile

| DH9 | dh9 | L+0.2 | G | r | O-Ring | |||

|---|---|---|---|---|---|---|---|---|

| GPS-L | GPS | GPS-P | 0÷200 Bar | 0÷400 Bar | ||||

| 15÷39.9 | 8÷14.9 | D-4.9 | 2.2 | 0.6÷0.4 | 0.4÷0.3 | 0.4 | 1.78 | |

| 40÷79.9 | 15÷39.9 | D-7.5 | 3.2 | 0.8÷0.5 | 0.5÷0.3 | 0.6 | 2.62 | |

| 80÷132.9 | 40÷79.9 | 15÷39.9 | D-11.0 | 4.2 | 0.8÷0.5 | 0.5÷0.3 | 1.0 | 3.53 |

| 133÷329.9 | 80÷132.9 | 40÷79.9 | D-15.5 | 6.3 | 1.0÷0.6 | 0.6÷0.4 | 1.2 | 5.34 |

| 330÷669.9 | 133÷329.9 | 80÷132.9 | D-21.0 | 8.1 | 1.0÷0.6 | 0.6÷0.4 | 1.8 | 6.99 |

| 670÷999.9 | 330÷669.9 | 133÷329.9 | D-24.5 | 8.1 | 1.2÷0.8 | 0.8÷0.5 | 1.8 | 6.99 |

| 670÷999.9 | 330÷669.9 | D-28.0 | 9.5 | 1.4÷0.8 | 0.8÷0.6 | 2.0 | 8.40 |

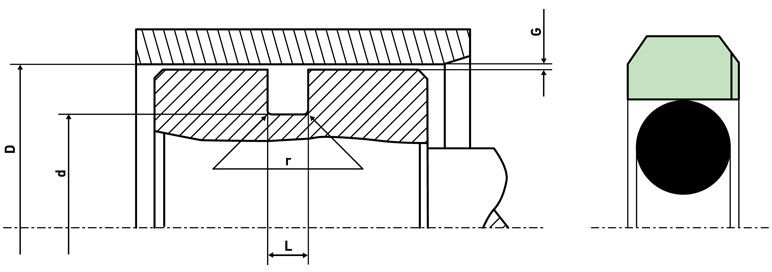

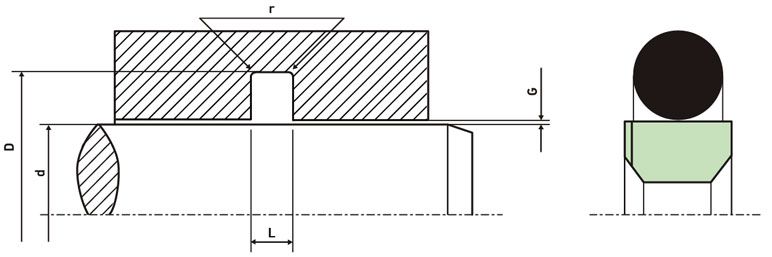

GPR | Essentially one-way seal profile

| DH9 | dh9 | L+0.2 | G | r | O-Ring | |||

|---|---|---|---|---|---|---|---|---|

| GPR-L | GPR | GPR-P | 0÷200Bar | 200÷400 Bar | ||||

| 17÷26.9 | 8÷16.9 | D-4.9 | 2.2 | 0.5÷0.3 | 0.4÷0.2 | 0.4 | 1.78 | |

| 27÷59.9 | 17÷26.9 | D-7.3 | 3.2 | 0.7÷0.3 | 0.5÷0.2 | 0.6 | 2.62 | |

| 60÷199.9 | 27÷59.9 | 17÷26.9 | D-10.7 | 4.2 | 0.8÷0.4 | 0.5÷0.3 | 1.0 | 3.53 |

| 200÷255.9 | 60÷199.9 | 27÷59.9 | D-15.1 | 6.3 | 0,9÷0.6 | 0.6÷0.4 | 1.2 | 5.34 |

| 256÷669.9 | 200÷255.9 | 60÷199.9 | D-20.5 | 8.1 | 1.0÷0.6 | 0.7÷0.4 | 1.8 | 6.99 |

| 670÷999.9 | 256÷669.9 | 200÷255,9 | D-24.0 | 8.1 | 1.1÷0.8 | 0.8÷0.5 | 1.8 | 6.99 |

| 670÷999.9 | 256÷669.9 | D-27.3 | 9.5 | 1.2÷1.0 | 1.0÷0.6 | 2.0 | 8.40 |

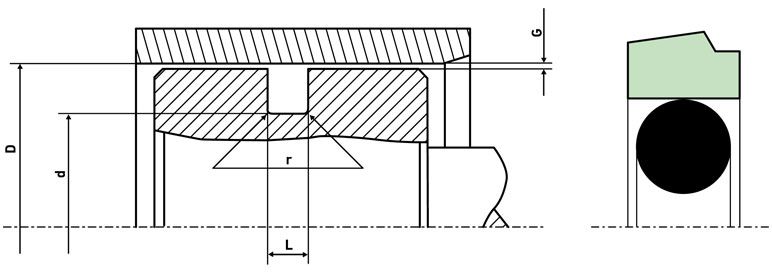

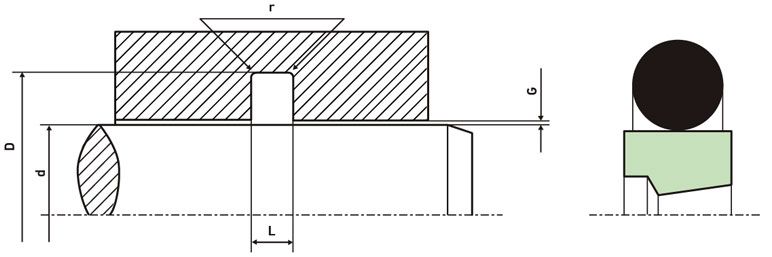

GCS | Double acting seal profile

| d h9 | D H9 | L+0.2 | G | r | 0-Ring | |||

|---|---|---|---|---|---|---|---|---|

| GCS-L | GCS | GCS-P | 0÷200 Bar | 200÷400 Bar | ||||

| 8÷18.9 | 3÷7.9 | d+4.9 | 2.2 | 0.4÷0.3 | 0.3÷0.2 | 0.4 | 1.78 | |

| 19÷37.9 | 8÷18.9 | d+7.3 | 3.2 | 0.5÷0.3 | 0.3÷0.2 | 0.6 | 2.62 | |

| 38÷199.9 | 19÷37.9 | 8÷18.9 | d+10.7 | 4.2 | 0.7÷0.4 | 0.4÷0.2 | 1.0 | 3.53 |

| 200÷255.9 | 38÷199.9 | 19÷37.9 | d+15.1 | 6.3 | 0.8÷0.6 | 0.6÷0.4 | 1.3 | 5.34 |

| 256÷649.9 | 200÷255.9 | 38÷199.9 | d+20.5 | 8.1 | 0.8÷0.6 | 0.6÷0.4 | 1.8 | 6.99 |

| 650÷999.9 | 256÷649.9 | 200÷255.9 | d+24.0 | 8.1 | 0.9÷0.7 | 0.7÷0.4 | 1.8 | 6.99 |

| 650÷999.9 | 256÷649.9 | d+27.3 | 9.5 | 1.0÷0.8 | 0.8÷0.6 | 2.5 | 8.40 |

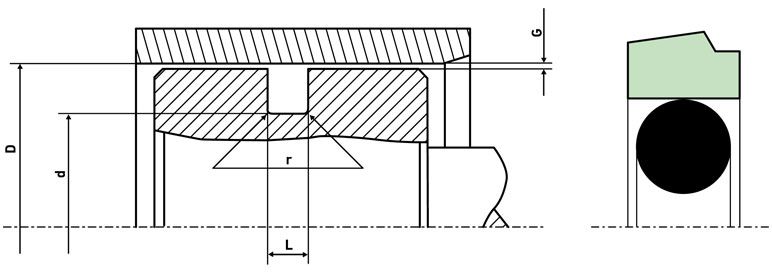

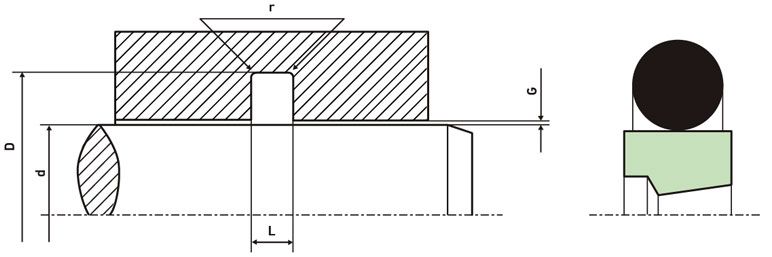

GCR | Essentially one-way seal profile

| d h9 | D H9 | L+0.2 | G | r | 0-Ring | |||

|---|---|---|---|---|---|---|---|---|

| GCR-L | GCR | GCR-P | 0÷200 Bar | 200÷400 Bar | ||||

| 8÷18.9 | 3÷7.9 | d+4.9 | 2.2 | 0.6÷0.4 | 0.4÷0.2 | 0.4 | 1.78 | |

| 19÷37.9 | 8÷18.9 | d+7.3 | 3.2 | 0.8÷0.5 | 0.5÷0.3 | 0.6 | 2.62 | |

| 38÷199.9 | 19÷37.9 | 8÷18.9 | d+10.7 | 4.2 | 0.8÷0.5 | 0.5÷0.3 | 1.0 | 3.53 |

| 200÷255.9 | 38÷199.9 | 19÷37.9 | d+15.1 | 6.3 | 1.0÷0.6 | 0.6÷0.4 | 1.3 | 5.34 |

| 256÷649.9 | 200÷255.9 | 38÷199.9 | d+20.5 | 8.1 | 1.0÷0.6 | 0.6÷0.4 | 1.5 | 6.99 |

| 650÷999.9 | 256÷649.9 | 200÷255.9 | d+24.0 | 8.1 | 1.2÷0.8 | 0.8÷0.6 | 1.5 | 6.99 |

| 650÷999.9 | 256÷649.9 | d+27.3 | 9.5 | 1.4÷1.0 | 1.0÷0.7 | 2.5 | 8.40 |

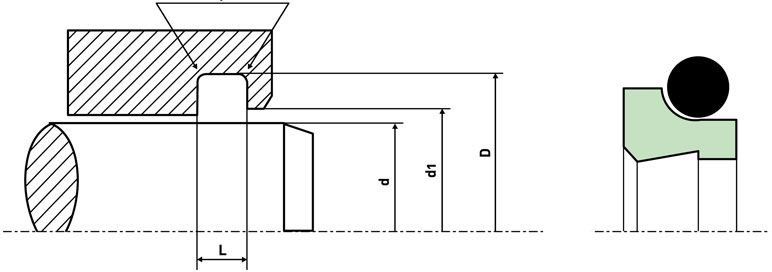

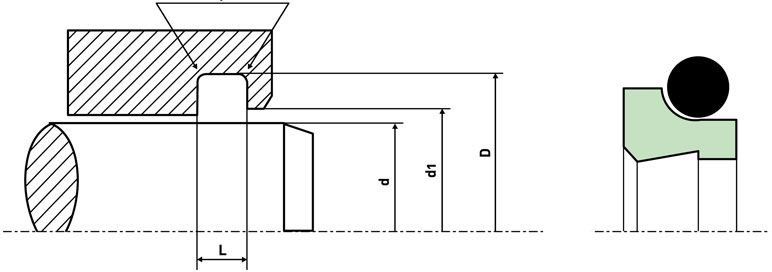

GR/C | Scraper

| d h9 | DH9 | L+0.2 | d1 H1 1 | r | O-Ring |

|---|---|---|---|---|---|

| GR/C | |||||

| 6÷11.9 | d+4.8 | 3.7 | d+1.5 | 0.4 | 1.78 |

| 12÷64.9 | d+6.8 | 5.0 | d+1.5 | 0.7 | 2.62 |

| 65÷250.9 | d+8.8 | 6.0 | d+1.5 | 1.0 | 3.53 |

| 251÷420.9 | d+12.2 | 8.4 | d+2.0 | 1.2 | 5.34 |

| 421÷650.9 | d+16.0 | 11.0 | d+2.0 | 1.5 | 6.99 |

| 651÷999.9 | d+20.0 | 14.0 | d+2.5 | 2.0 | 8.40 |

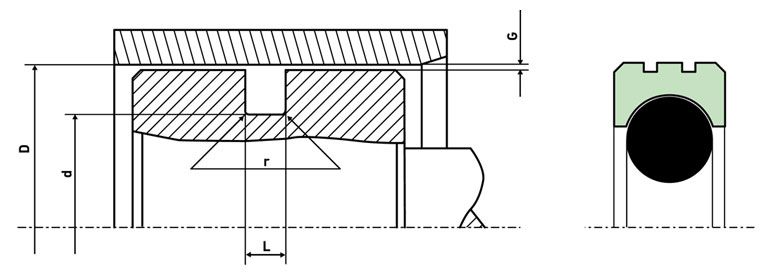

GPS/R | Rotary seal profile

| D H9 | d h9 | L+0.2 | r | G | 0-Ring | ||

|---|---|---|---|---|---|---|---|

| Serie | 0÷200 Bar | 200÷300 Bar | |||||

| GPS/R-0 | 6÷18.9 | D-4.9 | 2.2 | 0.3 | 0.3÷0.2 | 0.15÷0.1 | 1.78 |

| GPS/R-1 | 19÷37.9 | D-7.5 | 3.2 | 0.5 | 0.6÷0.4 | 0.3÷0.2 | 2.62 |

| GPS/R-2 | 38÷199.9 | D-11.0 | 4.2 | 0.7 | 0.6÷0.4 | 0.3÷0.2 | 3.53 |

| GPS/R-3 | 200÷255.9 | D-15.5 | 6.3 | 1.0 | 0.8÷0.6 | 0.4÷0.3 | 5.34 |

| GPS/R-4 | 256÷649.9 | D-21.0 | 8.1 | 1.2 | 0.8÷0.6 | 0.4÷0.3 | 6.99 |

| GPS/R-5 | 650÷999.9 | D-28.0 | 9.5 | 1.5 | 1.2÷0.9 | 0.6÷0.5 | 8.40 |

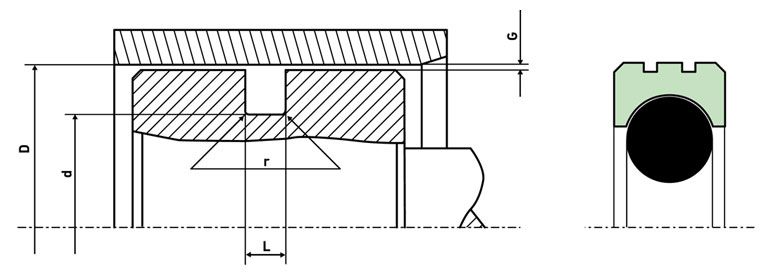

GCS/R | Rotary seal profile

| d h9 | D H9 | L+0.2 | r | G | 0-Ring | ||

|---|---|---|---|---|---|---|---|

| Serie | 0÷200 Bar | 200÷300 Bar | |||||

| GCS/R-0 | 6÷18.9 | d-4.9 | 2.2 | 0.3 | 0.3÷0.2 | 0.15÷0.1 | 1.78 |

| GCS/R-1 | 19÷37.9 | d-7.5 | 3.2 | 0.5 | 0.6÷0.4 | 0.3÷0.2 | 2.62 |

| GCS/R-2 | 38÷199.9 | d-11.0 | 4.2 | 0.7 | 0.6÷0.4 | 0.3÷0.2 | 3.53 |

| GCS/R-3 | 200÷255.9 | d-15.5 | 6.3 | 1.0 | 0.8÷0.6 | 0.4÷0.3 | 5.34 |

| GCS/R-4 | 256÷649.9 | d-21.0 | 8.1 | 1.2 | 0.8÷0.6 | 0.4÷0.3 | 6.99 |

| GCS/R-5 | 650÷999.9 | d-28.0 | 9.5 | 1.5 | 1.2÷0.9 | 0.6÷0.5 | 8.40 |

GPS | DOUBLE ACTIN SEAL PROFILE

| DH9 | dh9 | L+0.2 | G | r | O-Ring | |||

|---|---|---|---|---|---|---|---|---|

| GPS-L | GPS | GPS-P | 0÷200 Bar | 0÷400 Bar | ||||

| 15÷39.9 | 8÷14.9 | D-4.9 | 2.2 | 0.6÷0.4 | 0.4÷0.3 | 0.4 | 1.78 | |

| 40÷79.9 | 15÷39.9 | D-7.5 | 3.2 | 0.8÷0.5 | 0.5÷0.3 | 0.6 | 2.62 | |

| 80÷132.9 | 40÷79.9 | 15÷39.9 | D-11.0 | 4.2 | 0.8÷0.5 | 0.5÷0.3 | 1.0 | 3.53 |

| 133÷329.9 | 80÷132.9 | 40÷79.9 | D-15.5 | 6.3 | 1.0÷0.6 | 0.6÷0.4 | 1.2 | 5.34 |

| 330÷669.9 | 133÷329.9 | 80÷132.9 | D-21.0 | 8.1 | 1.0÷0.6 | 0.6÷0.4 | 1.8 | 6.99 |

| 670÷999.9 | 330÷669.9 | 133÷329.9 | D-24.5 | 8.1 | 1.2÷0.8 | 0.8÷0.5 | 1.8 | 6.99 |

| 670÷999.9 | 330÷669.9 | D-28.0 | 9.5 | 1.4÷0.8 | 0.8÷0.6 | 2.0 | 8.40 |

GPR | ESSENTIALLY ONE-WAY SEAL PROFILE

| DH9 | dh9 | L+0.2 | G | r | O-Ring | |||

|---|---|---|---|---|---|---|---|---|

| GPR-L | GPR | GPR-P | 0÷200Bar | 200÷400 Bar | ||||

| 17÷26.9 | 8÷16.9 | D-4.9 | 2.2 | 0.5÷0.3 | 0.4÷0.2 | 0.4 | 1.78 | |

| 27÷59.9 | 17÷26.9 | D-7.3 | 3.2 | 0.7÷0.3 | 0.5÷0.2 | 0.6 | 2.62 | |

| 60÷199.9 | 27÷59.9 | 17÷26.9 | D-10.7 | 4.2 | 0.8÷0.4 | 0.5÷0.3 | 1.0 | 3.53 |

| 200÷255.9 | 60÷199.9 | 27÷59.9 | D-15.1 | 6.3 | 0,9÷0.6 | 0.6÷0.4 | 1.2 | 5.34 |

| 256÷669.9 | 200÷255.9 | 60÷199.9 | D-20.5 | 8.1 | 1.0÷0.6 | 0.7÷0.4 | 1.8 | 6.99 |

| 670÷999.9 | 256÷669.9 | 200÷255,9 | D-24.0 | 8.1 | 1.1÷0.8 | 0.8÷0.5 | 1.8 | 6.99 |

| 670÷999.9 | 256÷669.9 | D-27.3 | 9.5 | 1.2÷1.0 | 1.0÷0.6 | 2.0 | 8.40 |

GCS | DOUBLE ACTING SEAL PROFILE

| d h9 | D H9 | L+0.2 | G | r | 0-Ring | |||

|---|---|---|---|---|---|---|---|---|

| GCS-L | GCS | GCS-P | 0÷200 Bar | 200÷400 Bar | ||||

| 8÷18.9 | 3÷7.9 | d+4.9 | 2.2 | 0.4÷0.3 | 0.3÷0.2 | 0.4 | 1.78 | |

| 19÷37.9 | 8÷18.9 | d+7.3 | 3.2 | 0.5÷0.3 | 0.3÷0.2 | 0.6 | 2.62 | |

| 38÷199.9 | 19÷37.9 | 8÷18.9 | d+10.7 | 4.2 | 0.7÷0.4 | 0.4÷0.2 | 1.0 | 3.53 |

| 200÷255.9 | 38÷199.9 | 19÷37.9 | d+15.1 | 6.3 | 0.8÷0.6 | 0.6÷0.4 | 1.3 | 5.34 |

| 256÷649.9 | 200÷255.9 | 38÷199.9 | d+20.5 | 8.1 | 0.8÷0.6 | 0.6÷0.4 | 1.8 | 6.99 |

| 650÷999.9 | 256÷649.9 | 200÷255.9 | d+24.0 | 8.1 | 0.9÷0.7 | 0.7÷0.4 | 1.8 | 6.99 |

| 650÷999.9 | 256÷649.9 | d+27.3 | 9.5 | 1.0÷0.8 | 0.8÷0.6 | 2.5 | 8.40 |

GCR | ESSENTIALLY ONE-WAY SEAL PROFILE

| d h9 | D H9 | L+0.2 | G | r | 0-Ring | |||

|---|---|---|---|---|---|---|---|---|

| GCR-L | GCR | GCR-P | 0÷200 Bar | 200÷400 Bar | ||||

| 8÷18.9 | 3÷7.9 | d+4.9 | 2.2 | 0.6÷0.4 | 0.4÷0.2 | 0.4 | 1.78 | |

| 19÷37.9 | 8÷18.9 | d+7.3 | 3.2 | 0.8÷0.5 | 0.5÷0.3 | 0.6 | 2.62 | |

| 38÷199.9 | 19÷37.9 | 8÷18.9 | d+10.7 | 4.2 | 0.8÷0.5 | 0.5÷0.3 | 1.0 | 3.53 |

| 200÷255.9 | 38÷199.9 | 19÷37.9 | d+15.1 | 6.3 | 1.0÷0.6 | 0.6÷0.4 | 1.3 | 5.34 |

| 256÷649.9 | 200÷255.9 | 38÷199.9 | d+20.5 | 8.1 | 1.0÷0.6 | 0.6÷0.4 | 1.5 | 6.99 |

| 650÷999.9 | 256÷649.9 | 200÷255.9 | d+24.0 | 8.1 | 1.2÷0.8 | 0.8÷0.6 | 1.5 | 6.99 |

| 650÷999.9 | 256÷649.9 | d+27.3 | 9.5 | 1.4÷1.0 | 1.0÷0.7 | 2.5 | 8.40 |

GR/C | SCRAPER

| d h9 | DH9 | L+0.2 | d1 H1 1 | r | O-Ring |

|---|---|---|---|---|---|

| GR/C | |||||

| 6÷11.9 | d+4.8 | 3.7 | d+1.5 | 0.4 | 1.78 |

| 12÷64.9 | d+6.8 | 5.0 | d+1.5 | 0.7 | 2.62 |

| 65÷250.9 | d+8.8 | 6.0 | d+1.5 | 1.0 | 3.53 |

| 251÷420.9 | d+12.2 | 8.4 | d+2.0 | 1.2 | 5.34 |

| 421÷650.9 | d+16.0 | 11.0 | d+2.0 | 1.5 | 6.99 |

| 651÷999.9 | d+20.0 | 14.0 | d+2.5 | 2.0 | 8.40 |

GPS/R | ROTARY SEAL PROFILE

| D H9 | d h9 | L+0.2 | r | G | 0-Ring | ||

|---|---|---|---|---|---|---|---|

| Serie | 0÷200 Bar | 200÷300 Bar | |||||

| GPS/R-0 | 6÷18.9 | D-4.9 | 2.2 | 0.3 | 0.3÷0.2 | 0.15÷0.1 | 1.78 |

| GPS/R-1 | 19÷37.9 | D-7.5 | 3.2 | 0.5 | 0.6÷0.4 | 0.3÷0.2 | 2.62 |

| GPS/R-2 | 38÷199.9 | D-11.0 | 4.2 | 0.7 | 0.6÷0.4 | 0.3÷0.2 | 3.53 |

| GPS/R-3 | 200÷255.9 | D-15.5 | 6.3 | 1.0 | 0.8÷0.6 | 0.4÷0.3 | 5.34 |

| GPS/R-4 | 256÷649.9 | D-21.0 | 8.1 | 1.2 | 0.8÷0.6 | 0.4÷0.3 | 6.99 |

| GPS/R-5 | 650÷999.9 | D-28.0 | 9.5 | 1.5 | 1.2÷0.9 | 0.6÷0.5 | 8.40 |

GCS/R | ROTARY SEAL PROFILE

| d h9 | D H9 | L+0.2 | r | G | 0-Ring | ||

|---|---|---|---|---|---|---|---|

| Serie | 0÷200 Bar | 200÷300 Bar | |||||

| GCS/R-0 | 6÷18.9 | d-4.9 | 2.2 | 0.3 | 0.3÷0.2 | 0.15÷0.1 | 1.78 |

| GCS/R-1 | 19÷37.9 | d-7.5 | 3.2 | 0.5 | 0.6÷0.4 | 0.3÷0.2 | 2.62 |

| GCS/R-2 | 38÷199.9 | d-11.0 | 4.2 | 0.7 | 0.6÷0.4 | 0.3÷0.2 | 3.53 |

| GCS/R-3 | 200÷255.9 | d-15.5 | 6.3 | 1.0 | 0.8÷0.6 | 0.4÷0.3 | 5.34 |

| GCS/R-4 | 256÷649.9 | d-21.0 | 8.1 | 1.2 | 0.8÷0.6 | 0.4÷0.3 | 6.99 |

| GCS/R-5 | 650÷999.9 | d-28.0 | 9.5 | 1.5 | 1.2÷0.9 | 0.6÷0.5 | 8.40 |

FASCE GUIDA

Una famiglia di prodotti realizzati con speciali mescole di PTFE e tecnologie dedicate per soddisfare le esigenze dei clienti Guarniflon® che operano nel settore dell’oleodinamica.

Gradi in PTFE caricato con bronzo, carbone, fibra di vetro, grafite o altri filler espressamente progettati per migliorare proprietà quali:

- Resistenza all'usura

- Coefficiente d'attrito

- Resistenza alla compressione

Spessori da 1,5 mm. fino a 5 mm. Larghezze da 4 mm. fino a 300 mm.

Disponibili:

Disponibili:

- con spigoli vivi

- con smussi su 2 o 4 angoli

- godronate su 1 o 2 lati

- cementate su 1 o 2 lati

| Lunghezze Rotoli | |

|---|---|

| Spessore mm. | Lunghezza mt. |

| 1.5 | 35 |

| 2 | 25 |

| 2.5 | 20 |

| 3 | 16 |

| 4 | 24 |

MATERIALI

PTFE VERGINE

Buona resistenza chimica. Debole resistenza all’usura.

Eccellente coefficiente d’atrito

PTFE + FIBRA DI VETRO

Superiore resistenza all’usura. Superiore resistenza chimica. Buona resistenza alla compressione.

PTFE + CARBONE

Buona conduttività termica ed elettrica. Buona resistenza alla deformazione. Eccellente resistenza alla compressione con un basso coefficiente d’attrito ed un’alta resistenza all’usura. Superiore resistenza chimica.

PTFE + BRONZO

Superiore resistenza alla compressione.Buona resistenza all’usura alta conduttività termica. Guarniflon dispone di più di 80 gradi di PTFE caricati in grado di offrire soluzioni alle applicazioni più problematiche. Disponibili su richiesta.

Buona resistenza chimica. Debole resistenza all’usura.

Eccellente coefficiente d’atrito

PTFE + FIBRA DI VETRO

Superiore resistenza all’usura. Superiore resistenza chimica. Buona resistenza alla compressione.

PTFE + CARBONE

Buona conduttività termica ed elettrica. Buona resistenza alla deformazione. Eccellente resistenza alla compressione con un basso coefficiente d’attrito ed un’alta resistenza all’usura. Superiore resistenza chimica.

PTFE + BRONZO

Superiore resistenza alla compressione.Buona resistenza all’usura alta conduttività termica. Guarniflon dispone di più di 80 gradi di PTFE caricati in grado di offrire soluzioni alle applicazioni più problematiche. Disponibili su richiesta.